Home | Standards

Codes and standards

Summary of regulations

European Elevators

In Europe the elevator sector is regulated by EU Directives based on the concept of Essential Safety Requirements; the first directive (95/16/EC) is dated 1995, replaced later by the one currently in force (2014/33/EU). The directives then form the basis for the drafting of standards written by CEN (European Committee for Standardization) and declared harmonized by the European Commission, which establishes their property of meeting the Essential Safety Requirements (RES) of the Lifts Directive.

Compliance with applicable regulations guides each of our projects for your safety

Regulations

The evolution of

European regulations

Since1999, the design and installation of elevators in Europe has been regulated by two so-called New Approach product directives:

- 95/16/EC (no longer in force)

-

2014/33/EU (currently still in force)

These Directives set out the Requirements to be met by manufacturers of safety components and by installers of elevators in order to place their product within the European Economic Area. The Directives established the absolute mandatory compliance with Essential Safety and Health Protection Requirements (RES). To date, the only Directive in force is 2014/33/EU, which replaced the previous one as of April 20, 2016. For elevators, there are harmonized standards which give presumption of conformity to Directive 2014/33/EU; any situations of non-compliance with the harmonized standards are not prohibited, but the safety conditions established by the proposed solution must still comply with the RES through an appropriate Risk Assessment and must be submitted for analysis and approval by a Notified Body.

Reference Standards EN 81-20 AND EN 81-50

Introduced in August 2014, the European Standards for the design and manufacture of elevators have brought considerable benefits in terms of accessibility and safety for both passengers and maintainers. EN 81-20 sets out the safety requirements for the construction and installation of elevators; EN 81-50, on the other hand, defines the requirements for calculations, verifications and testing of components. These standards clarify and improve previous requirements on building interface. They replaced the previous standards EN 81-1 and EN 81-2. The main contents in terms of necessary requirements on safety found in EN 81-20 and EN 81-50 are articulated in the following points.

PASSENGER SAFETY CONTENT

Requirements related to uncontrolled car movement - Unintended Car Movement (UCM) - and overspeeding of the car uphill

The requirements for mechanisms that protect against the risk of uncontrolled movement of the cabin away from the floor and the requirement for protection against overspeeding when climbing the cabin are explained.

Tecno Elevators provides solutions that include the requirements of the Standards to perimpede that uncontrolled car movement occurs through daily verification of the proper functioning of the machine brake elements and simplification of manual emergency operation.

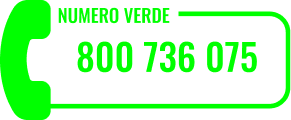

Door detection system

When choosing a reliable partner for the installation, maintenance, modernization, or replacement of an elevator, it is important to consider expertise, making sure they have a thorough understanding of regulations related to safety, accessibility, and sustainability to ensure reliability and comfort. It is crucial to opt for those who offer comprehensive service, including customizable and predictive maintenance, with continuous monitoring to anticipate and resolve problems, avoiding unexpected downtime and extending the life of the system. Quality of service is essential, with qualified and up-to-date technicians ready to act quickly, supported by 24-hour customer service and a widespread team throughout the territory. The partner's experience and commitment to innovation are key to offering advanced solutions in terms of safety, eco-efficiency and design.

Cabin door locking mechanism

Elevators must incorporate a car door locking mechanism that prevents the doors from being opened from inside the car when the car is outside the floor door release zone. This requirement was created to prevent passengers trapped in the car from accidentally falling from the car into the elevator shaft should they attempt to exit a locked car between floors. TecnoAscensori offers this type of mechanism for all its elevator solutions.

Fire classification of materials used for the cabin

The materials used for the floor, walls and ceiling of the cabin must meet the stringent requirements below, where C and Cfl refer to the "reaction to fire" classification, s (smoke) and d (drops) refer to the classification of materials with respect to smoke and drip formation (molten particles), respectively:

- Floor: Cfl s2

- Walls: C s2 d1

- Ceiling: C s2 d0

Strength of landing and cabin doors and cabin walls

EN 81-20 includes mechanical strength requirements for landing and cabin doors, as well as for cabin walls. Doors must include devices to hold their constituent panels in place should the main guiding elements fail to function as they should. The landing and cabin doors must also be tested to withstand an impact force equivalent to that of a person hitting the door at its rate of movement. The strength requirements of cabin walls shall be such as to ensure that they can withstand the forces equivalent to a person pushing against them.

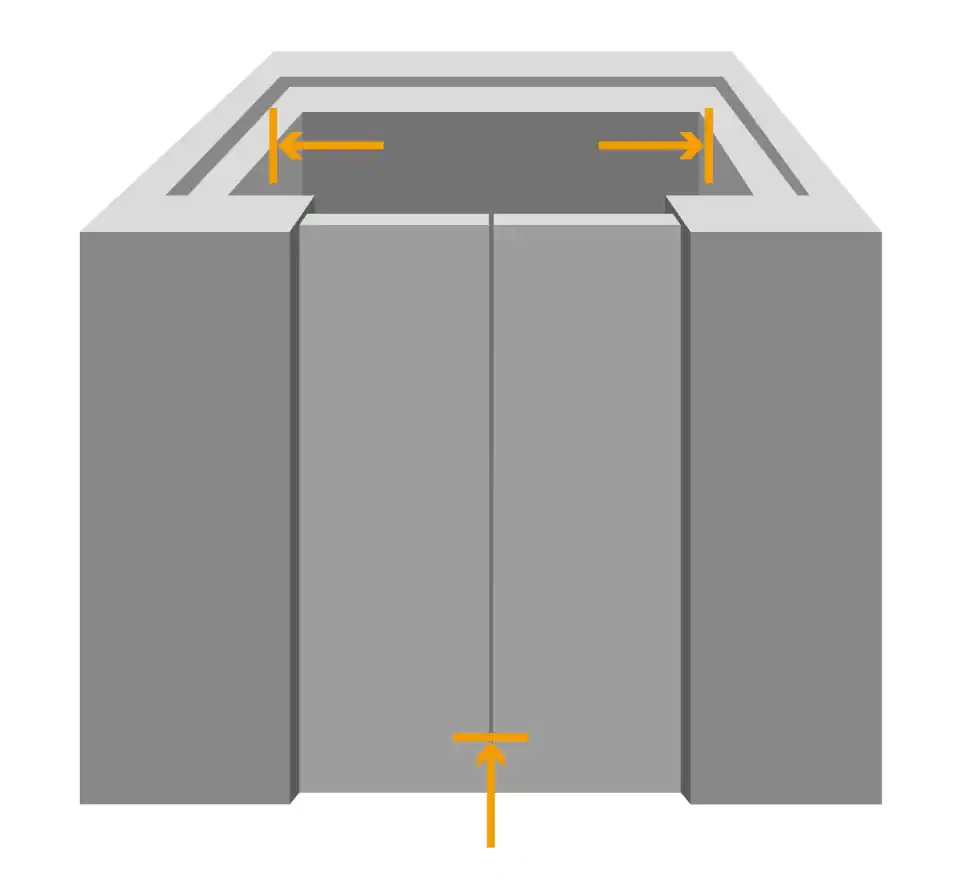

Cabin and compartment lighting

EN 81-20 requires specified cabin and compartment lighting intensity. The type of cabin lighting must provide an intensity of at least 100 lux, and emergency lighting on the cabin roof of at least 5 lux for one hour must be provided to increase safety for maintenance workers. Requirements for permanent compartment lighting, on the other hand, are divided into:

- At least 50 lux at 1 m above the cabin roof within its vertical projection

- At least 50 lux at 1 m above the floor of the raceway pit in any place where a person can stand,work, and/or move between work areas

- At least 20 lux outside the positions defined above, excluding shadows created by the cabin or components

SAFETY CONTENT FOR MAINTENANCE WORKERS IN SERVICE ACTIVITIES

Access doors to the machinery rooms and the pit and location of the control device in the pit

EN 81-20 includes requirements that aim to make it increasingly safe for perimanutors to access and work in the pit and in the machinery room/space. In fact, requirements for the size, strength and location of means of access, such as ladders, are defined. Access requirements for pits deeper than 2.5 m are stringent, and an access door other than the lowest floor door must be required. In addition, the standard requires that a control device be placed in the pit for maneuvering inspection of the cab to prevent maintenance workers from using ladders or stools to reach components under the cab. The control device must be located near the refuge spaces in the pit. There must be a normal operation reset function located outside the compartment.

Access, inspection and rescue doors and counterweight parachutes

EN 81-20 requires "doors" for access and inspection of the travel compartment to direct as safe and easy access as possible for maintenance workers. The requirements are as follows:

- Access doors to the machinery room and the running room should have a minimum height of 2 m and a minimum width of 0.6 m

- Access doors to idler pulley rooms must have a minimum height of 1.4 m and a minimum width of 0.6 m

- Access hatches for people to the machinery and idler pulley rooms must provide a clear passage of at least 0.8 m x 0.8 m and must be counterweighted.Emergency doors must have a minimum height of 1.8 m and a minimum width of 0.5 m

- Inspection doors must have a maximum height and width of 0.5 m

The standard then requires that the counterweight be equipped with a chute in case there are accessible spaces located under the pit, for example, when the pit is located above a garage or storage room in the basement (passable under pit).

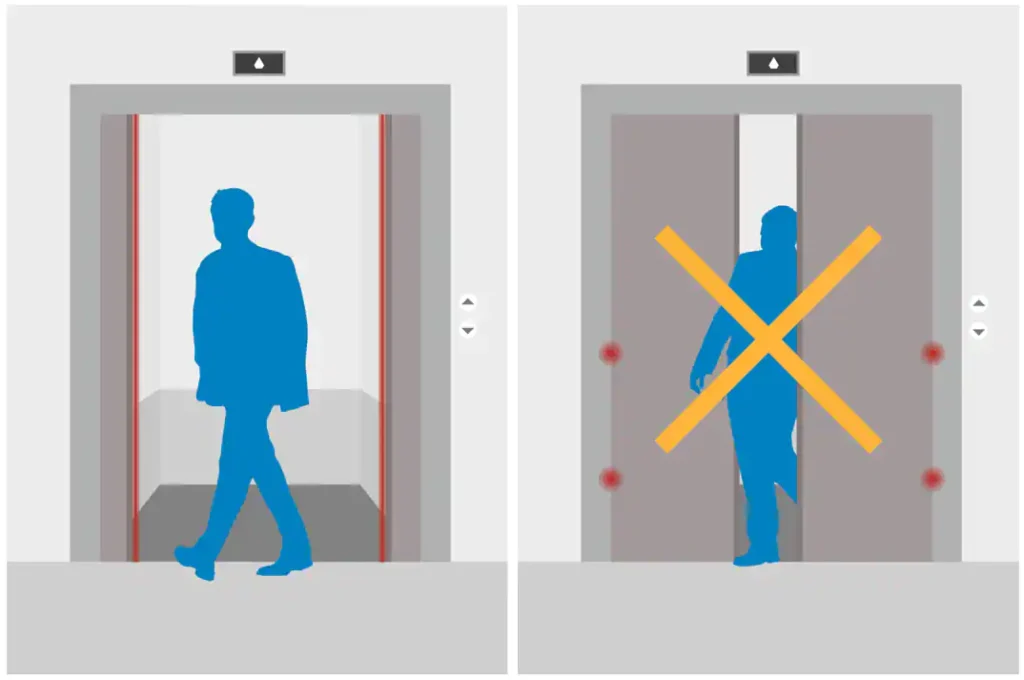

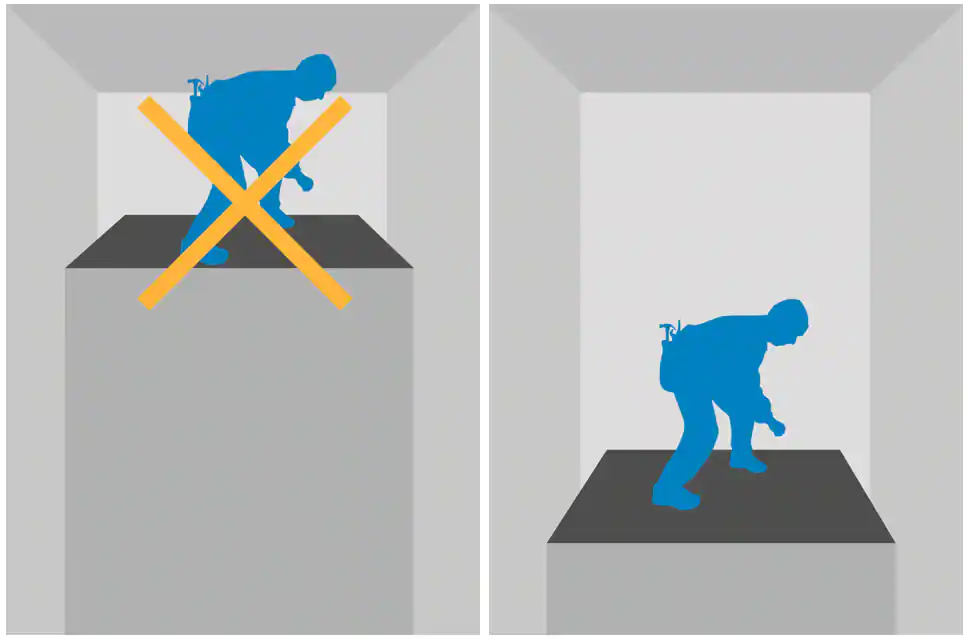

Shelter spaces on the cabin roof and in the pit

The volume requirements for shelter spaces on the cabin roof and in the pit are:

- Standing position: 0.4 x 0.5 m (horizontal dimensions), 2 m (height)

- Crouched position: 0.5 x 0.7 m (horizontal dimensions), 1 m (height)

- Lying position (valid only for the pit): 0.7 x 1 m (horizontal dimensions), 0.5 m (height)

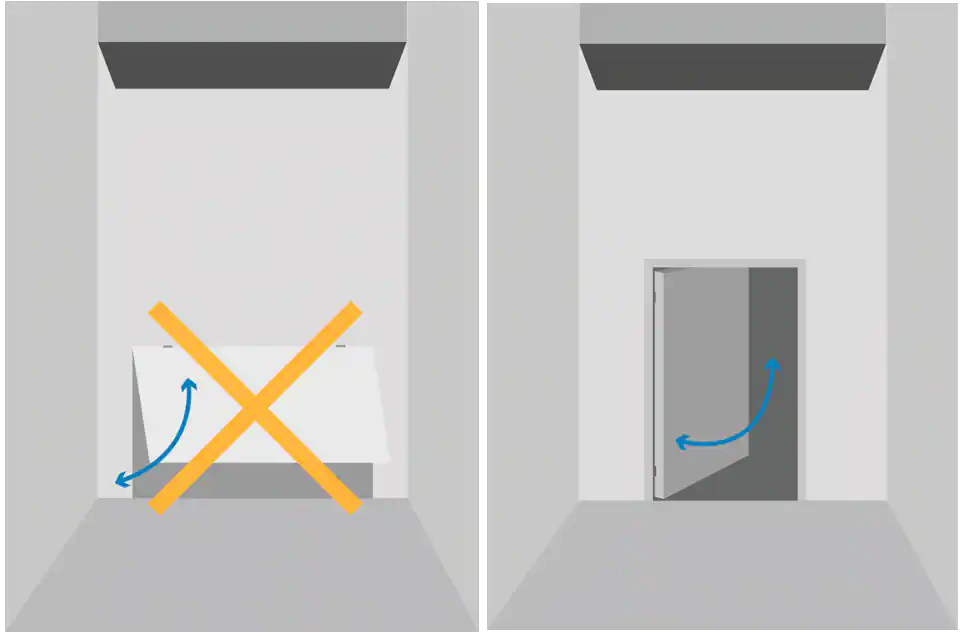

EN 81-20 requires that the floor door giving access to the pit must always be able to be opened from inside the pit so that maintenance workers can exit the pit, even if the floor door was closed.

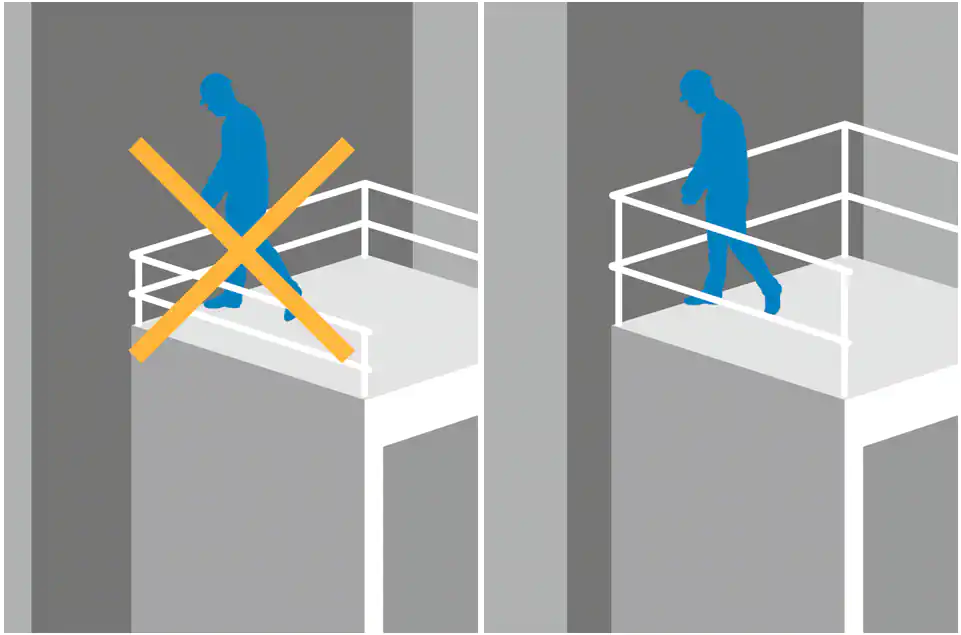

Cab roof railings

Railings on the elevator car roof have well-defined strength specifications as well as height requirements; this reduces the risk that maintenance workers working on the car roof could fall into the shaft. The key requirement defines the following:

- If the horizontal clear distance between the inner edge of the handrail of the parapet and the compartment wall is up to 500 mm, the height of the parapet must be at least 700 mm

- If this distance exceeds 500 mm, the height of the guardrail should be at least 1,100 mm

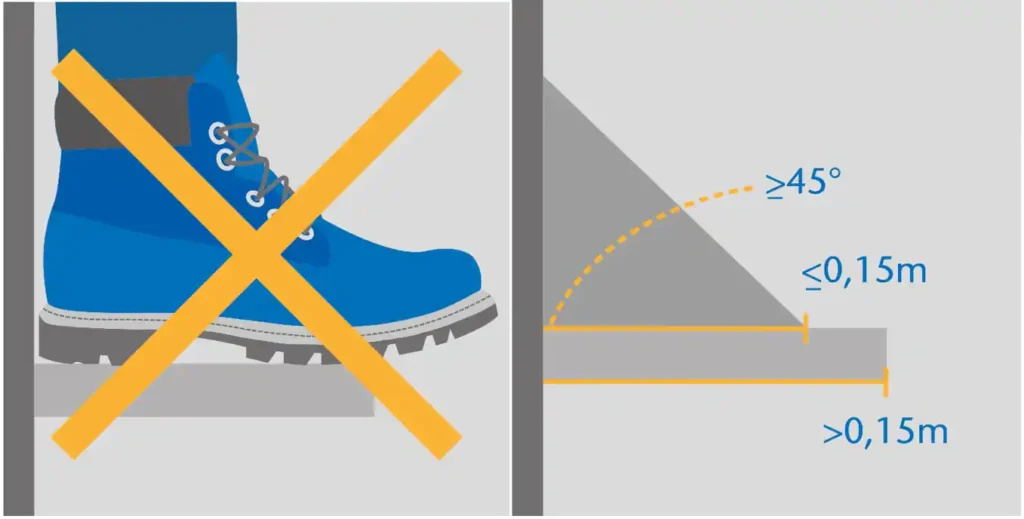

Horizontal projections in the compartment

Any horizontal projection from a wall to the shaft or from a horizontal beam with a depth greater than 0.15 m, including separation beams, must be protected against the possibility of a person stationing there, unless access is prevented by a guardrail on the car roof. EN 81-20 confirms the obligation between the manufacturer/designer and the elevator supplier to exchange information concerning the installation.

design requirements

REQUIREMENTS AFFECTING THE DESIGN OF BUILDINGS

EN 81-20 defines some requirements to be met by the building designer. They apply to the elevator shaft as follows:

- All glass used as compartment walls or within the compartment must be of laminated type

-

The definition of shaft ventilation is the responsibility of the building designer. The elevator installer must provide all necessary information in this regard such as, for example, heat dissipation by elevator components. This approach facilitates the design of energy-efficient buildings, where ventilation requirements are determined on the basis of the most energy-efficient solution, while simultaneously taking into account the working conditions of the technicians working in the elevator shaft and the comfort for passengers inside the car

Fire extinguishers may be located within the compartment. If sprinkler systems are used, sprinkler activation should be possible only when the elevator is stopped at one floor and the power supply to the elevator and lighting circuits is automatically disconnected from the smoke or fire detection system.